Straatman Smart Bollard

Revolutionizing Dock Safety and Efficiency

The Smart Bollard, though resembling a conventional dock bollard, represents a leap forward in enhancing safety and efficiency in mooring operations. Installed permanently on quays, this innovative solution is equipped with cutting-edge sensors designed to measure the load on mooring lines. These measurements capture the structural movements resulting from tension in the mooring lines, furnishing invaluable data to port authorities, terminal operators, and vessel crews. From cruise ships to container and bulk carriers, the Smart Bollard revolutionizes dock safety for all seagoing vessels.

Why Opt for a Smart Bollard?

Traditionally, the measurement of mooring line loads using bollards has been impossible. This lack of precise load data necessitates ports to assume maximum mooring loads, particularly crucial during adverse weather conditions with high waves, strong currents, and gusts. Excessive loads on mooring lines pose a serious risk, potentially leading to rope breakage and vessel detachment, resulting in severe accidents. Smart Bollards mitigate these risks by providing real-time insights into mooring line loads, enhancing safety by preventing accidents and ensuring vessel stability during loading and unloading operations.

Moreover, the Smart Bollard contributes to operational efficiency by maintaining constant mooring line loads, thereby reducing ship movement and facilitating smoother and safer cargo handling operations.

Key Features and Benefits:

-

Enhanced Safety: Real-time load monitoring and force predictions bolster safety measures for both operators and assets.

-

Comprehensive Overview: Understanding mooring forces in diverse environments facilitates efficient vessel movement.

-

Optimized Dock Capacity: Insights into quay capabilities may allow for the mooring of larger ships.

-

Resource Efficiency: Predictive data minimizes the need for costly resources like tugboats.

-

Long-Term Data Insights: Continuous data collection offers a holistic view of berth and vessel forces, aiding in port development and operational refinement.

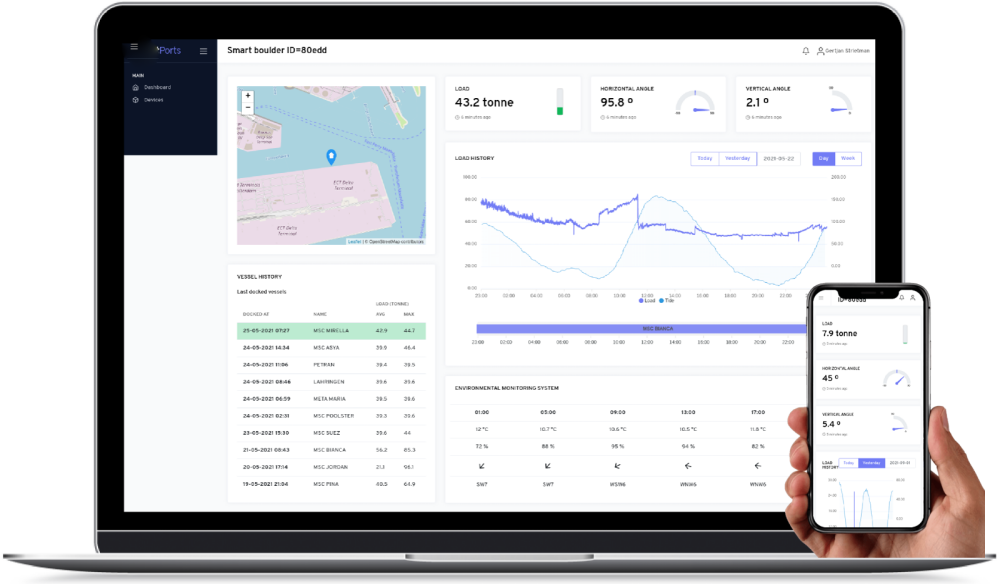

Data Connectivity and Integration:

The Smart Bollard offers flexible connectivity options, including both ethernet and wireless connectivity. An ethernet connection necessitates a separate switchbox for data transmission to the cloud, while wireless operations require an on-site gateway.

Cloud and API Integration:

Data transmitted to the cloud (via AWS) is accessible through our portal, which also provides weather and current data and accommodates a vessel database. This system is integrated in the Straatman MoorControl Software and seamlessly integrates with other platforms through a standard API, enabling enhanced data utilization and interoperability.

Data Displayed and Stored:

-

Load on bollard

-

Line direction

-

Line Angle

-

Tide level

-

Weather data

-

Vessel history (AIS data)

Print Product

© 2025 DSS Protection. All Rights Reserved. | Web Design: immediac.com